Is your engine's fuel delivery system acting up? Perhaps you're dealing with a fuel line replacement or an upgrade project? Understanding the ins and outs of 3/16" fuel lines is critical for ensuring safe and efficient operation. This guide provides a comprehensive look at the uses of 3/16" fuel line, covering everything from material types to proper installation techniques and common troubleshooting tips, ensuring your fuel system works reliably. So let's dive in.

All About 3/16" Fuel Line Uses and Installation

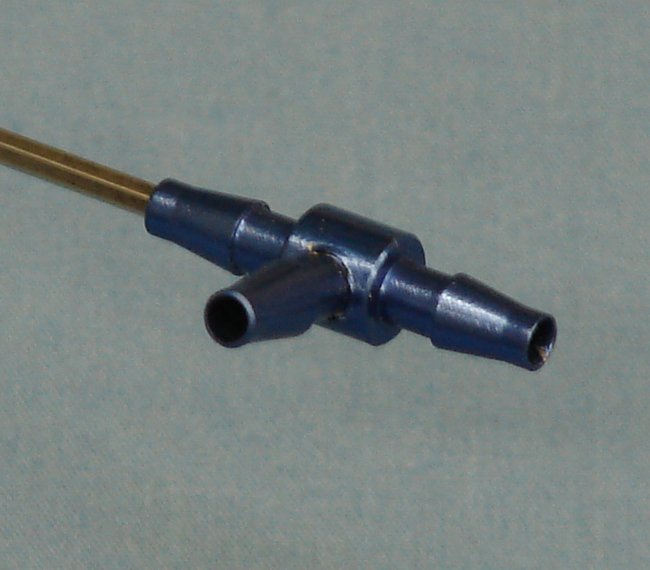

The 3/16" fuel line is a vital component in many fuel systems, particularly in smaller engines, motorcycles, ATVs, and even some classic cars. It's a fuel line with aninner diameter of 3/16 of an inch(approximately 4.76 mm). Its significance stems from its ability to handle relatively low fuel flow requirements while maintaining adequate fuel pressure. The 3/16" size is common because it provides a good balance between flexibility, ease of routing, and fuel delivery capacity for smaller engines.

Historically, fuel lines were often made of rubber, which was prone to degradation from exposure to gasoline, especially those containing ethanol. Over time, fuel line technology advanced, leading to the development of more durable materials likethermoplastic elastomers (TPE),fluoroelastomers (FKM)(like Viton), and evenstainless steel. These newer materials offer improved resistance to fuel additives, temperature fluctuations, and general wear and tear, extending the lifespan and reliability of the fuel system.

What sets the 3/16" fuel line apart is its versatility. It's small enough to be easily routed through tight spaces yet robust enough to handle the fuel pressure requirements of many smaller engines. It's also relatively inexpensive compared to larger diameter lines, making it a popular choice for various applications. While larger fuel lines might be necessary for high-performance engines demanding significant fuel volume, the 3/16" line offers an ideal solution for applications where fuel efficiency and space constraints are paramount. The material choices also impact its use case. For example, for fuel injection systems that are common on cars, it is better to use higher pressure fuel line.

Expert mechanics often recommend using high-quality fuel lines from reputable manufacturers. They emphasize the importance of matching the fuel line material to the type of fuel being used to prevent premature degradation. One seasoned mechanic shared a story of a vintage motorcycle repair where using an ethanol-resistant 3/16" fuel line completely resolved a recurring fuel leak issue caused by the original rubber line deteriorating. This simple upgrade significantly improved the motorcycle's reliability and performance.

Benefits of 3/16" Fuel Line for Users

Using a 3/16" fuel line enhances user experience primarily through improved reliability and ease of maintenance. For example, think about an ATV owner who regularly navigates rough terrain. A durable 3/16" fuel line made of TPE or stainless steel will resist punctures and abrasions far better than a standard rubber line. This translates to fewer breakdowns and less time spent on repairs in the field.

Consider a scenario where a classic car owner replaces their old, brittle rubber fuel lines with new 3/16" ethanol-resistant lines. The new lines not only eliminate fuel leaks but also improve engine performance by maintaining consistent fuel pressure.

Compared to larger diameter fuel lines, the 3/16" line is much easier to route in tight engine compartments or along complex chassis configurations. Its smaller size allows for more flexible installation, reducing the risk of kinks and bends that can restrict fuel flow. While larger fuel lines might be required for high-performance applications needing greater fuel volume, the 3/16" line offers a practical and cost-effective solution for many standard engines.

Data supports the effectiveness of using appropriate fuel lines. Studies have shown that fuel systems using ethanol-resistant lines experience significantly fewer failures due to fuel degradation compared to systems using standard rubber lines. Similarly, correctly sized fuel lines (like 3/16" for specific engine types) contribute to optimal fuel pressure, directly impacting engine efficiency and power output.

How to Use 3/16" Fuel Line

Here's a step-by-step guide on how to use and install a 3/16" fuel line properly:

1. Preparation & Safety

Before anything else,safety is paramount. Disconnect the negative battery cable to prevent sparks. Work in a well-ventilated area, away from open flames or potential ignition sources. Gather all necessary tools and materials, including the new 3/16" fuel line, fuel line clamps, a fuel line disconnect tool (if required), safety glasses, and gloves. Make sure to have a container ready to catch any spilled fuel.

Best Practices: Always use the correct type of fuel line for the fuel you're using (e.g., ethanol-resistant for modern gasoline). Double-check the fuel line's pressure rating to ensure it meets or exceeds the system's requirements.

2. Removing the Old Fuel Line

Carefully locate the fuel line you need to replace. If necessary, consult a repair manual or online diagrams to identify the correct line. If the fuel line is connected with fuel line clamps, use pliers or a screwdriver to loosen and remove them. If quick-disconnect fittings are used, employ the appropriate fuel line disconnect tool to release the fitting without damaging it. Gently pull the old fuel line away from the connection points, being prepared for some fuel spillage.

Common Mistakes to Avoid: Avoid using excessive force when removing fuel lines, as this can damage fittings or fuel system components. Never use a sharp object to puncture a fuel line to drain it, as this can create a fire hazard.

3. Installing the New 3/16" Fuel Line

Measure the length of the old fuel line and cut the new 3/16" fuel line to the same length using a fuel line cutter or a sharp utility knife. Ensure the cut is clean and square to prevent leaks. Slide fuel line clamps onto both ends of the new fuel line. Push the fuel line onto the connection points until it's fully seated. Securely tighten the fuel line clamps to create a leak-proof seal. If using quick-disconnect fittings, ensure they are properly engaged and locked.

Further Steps: Double-check all connections to ensure they are secure. Inspect the fuel line routing to avoid kinks or sharp bends. Reconnect the negative battery cable. Start the engine and check for any fuel leaks.

Tips Before Using 3/16" Fuel Line

Before diving into the installation, preparation is key. First and foremost, verify thefuel line's compatibilitywith the type of fuel you'll be using. Ethanol-blended fuels are notorious for degrading standard rubber lines, so using an ethanol-resistant line is critical.

Also, inspect the fuel line for any signs of damage before installation. Cracks, kinks, or abrasions can compromise its integrity and lead to leaks. Ensure that the fuel line is properly sized for your application. While 3/16" is a common size, using the wrong diameter can affect fuel pressure and engine performance.

Ignoring these tips can lead to serious consequences. A degraded fuel line can cause fuel leaks, leading to engine damage, reduced fuel efficiency, and potentially a fire hazard. An incorrectly sized fuel line can result in poor engine performance, including stalling, hesitation, and reduced power.

Common Issues and Solutions

One common issue isfuel leaksat the connection points. This often occurs when the fuel line clamps are not tightened sufficiently or if the fuel line is not fully seated on the fitting. The solution is to tighten the clamps securely, ensuring they are positioned correctly on the fuel line. If the leak persists, inspect the fuel line for damage or consider replacing the clamps.

Another potential problem isfuel line degradationdue to exposure to incompatible fuels. This can cause the fuel line to become brittle and crack, leading to leaks. The solution is to replace the fuel line with a fuel-resistant material, such as TPE or Viton. Always use the correct type of fuel line for the fuel being used.

Kinks and bendsin the fuel line can also restrict fuel flow, causing engine performance issues. The solution is to reroute the fuel line to eliminate any sharp bends or kinks. Use smooth, gradual curves to maintain unrestricted fuel flow. If necessary, use fuel line supports to prevent sagging or bending. Using the correct fuel line is critical to solving many of these issues.

Conclusion

The 3/16" fuel line is a versatile and essential component for many fuel systems. Understanding its uses, benefits, and proper installation techniques is crucial for ensuring reliable and efficient engine operation. By using the right materials, following proper installation procedures, and addressing potential issues promptly, individuals can maximize the lifespan and performance of their fuel systems. It's about more than just replacing a part; it's about ensuring the safe and efficient operation of your engine. So, take the time to understand your fuel system, choose the right components, and implement these practices in your daily life.