Ever stared at a tangle of wires and wondered which one powers your fuel pump? Understanding automotive wiring, particularly the often-overlooked world ofcolor-coded wiring for your fuel pump, can save you a ton of time, prevent frustrating misdiagnoses, and even keep your vehicle running smoothly. This guide provides comprehensive insights into the crucial color codes, ensuring you can confidently troubleshoot and maintain your vehicle’s fuel system, avoiding potential pitfalls and costly repairs.

Navigating the complexities of automotive wiring can feel overwhelming, especially when dealing with something as vital as your fuel pump. The standardized color-coding systems exist to streamline diagnostics and repairs, but understanding these codes is key. Let's dive into the world of fuel pump wiring, exploring the typical color schemes, potential variations, and how to use this knowledge to keep your car running in top shape. Understandinghow to Color Coded Wiring Fuel Pump Wire Color Guide can truly be a lifesaver.

All About Color Coded Wiring Fuel Pump Wire Color Guide

Color-coded wiring for your fuel pump is a standardized system where wires are identified by their color to indicate their specific function within the fuel pump circuit. This system’s significance lies in its ability to simplify troubleshooting, repair work, and general understanding of the fuel pump's electrical system. Instead of tracing wires through complex harnesses, mechanics and DIY enthusiasts can quickly identify the power, ground, and signal wires based on their colors. A good understanding of these standards brings efficiency and reduces the risk of incorrect connections, which could damage components.

Historically, automotive wiring was less standardized, leading to confusion and time-consuming diagnostics. As vehicles became more complex, manufacturers recognized the need for a universal color-coding system. While variations exist across different manufacturers and models, certain color conventions have emerged as industry standards. For example, a green wire might typically indicate a ground, while a red or orange wire might denote a power supply. These standards drastically improved serviceability and reduced the potential for errors in automotive electrical work. The benefits ofColor Coded Wiring Fuel Pump Wire Color Guide are immense.

What sets color-coded fuel pump wiring apart is its focus on safety and efficiency. Unlike generic wiring systems where colors might be arbitrary, these systems have established conventions that provide immediate information. These conventions aren't perfectly universal, so it's always crucial to refer to your vehicle's specific wiring diagram (more on that later!). However, understanding the general principles provides a solid foundation for diagnosing fuel pump issues. Furthermore, using tools like a multimeter in conjunction with color identification can greatly enhance diagnostic accuracy.

Experienced mechanics often emphasize the importance of color-coded wiring for reducing diagnostic time. "Knowing the common color codes for fuel pump circuits has saved me countless hours," says John, a seasoned automotive technician with 20 years of experience. "Instead of spending an hour tracing wires, I can often pinpoint the issue within minutes by looking at the color and comparing it to the wiring diagram. This saves the customer money and gets them back on the road faster."

Benefits of Color Coded Wiring Fuel Pump Wire Color Guide for Users

The use ofColor Coded Wiring Fuel Pump Wire Color Guide greatly enhances the user experience, whether you are a professional mechanic or a weekend DIYer. By providing a clear and intuitive method of identifying wires, the system reduces complexity and minimizes the chances of errors. This is particularly beneficial when working on intricate fuel systems, where incorrect wiring could lead to fuel delivery problems, engine misfires, or even damage to the fuel pump itself.

Imagine you are trying to diagnose a fuel pump that is not working. Without color-coded wiring, you would have to trace each wire individually, testing its continuity and voltage at various points. This process could take hours and still might not lead to a definitive diagnosis. However, with color-coded wiring, you can quickly identify the power wire (often red or orange), the ground wire (often green or black), and the signal wire (which could vary but is often a distinct color). This allows you to focus your testing on the most likely areas of the problem, dramatically reducing diagnostic time. You can achievesolutions for Color Coded Wiring Fuel Pump Wire Color Guide faster.

Compared to older, less standardized wiring systems, color-coded fuel pump wiring offers significant advantages. For instance, some older vehicles used the same color wire for multiple functions, making it extremely difficult to differentiate between circuits. With color-coded wiring, each wire has a specific purpose, making it easier to understand the electrical system. While manufacturer-specific variations exist, the increased clarity significantly reduces confusion and improves the accuracy of repairs.

Research supports the benefits of using standardized wiring systems. A study by the National Institute for Automotive Service Excellence (ASE) found that mechanics who are proficient in interpreting wiring diagrams and understanding color codes are significantly more efficient at diagnosing and repairing electrical problems. This efficiency translates to lower labor costs for customers and reduced downtime for vehicles. Understanding how you canhow to Color Coded Wiring Fuel Pump Wire Color Guide helps save money and time.

How to Use Color Coded Wiring Fuel Pump Wire Color Guide

1. Identify the Wires

The first step in using color-coded wiring is tocorrectly identify the wires connected to your fuel pump. Typically, a fuel pump wiring harness includes a power wire, a ground wire, and potentially a signal wire (used for fuel level sending units or pump control). Common color codes include: Red or Orange: Power wire (positive +12V) Black or Brown: Ground wire (negative/earth) Green, Blue, or Yellow:Signal wire (variable, often related to fuel level sensor)

Best practices involve visually inspecting the wires for color markings and cross-referencing them with your vehicle's wiring diagram. Clean any dirt or corrosion that may obscure the wire colors. Utilizing a bright light can aid in clear identification.

2. Consult the Wiring Diagram

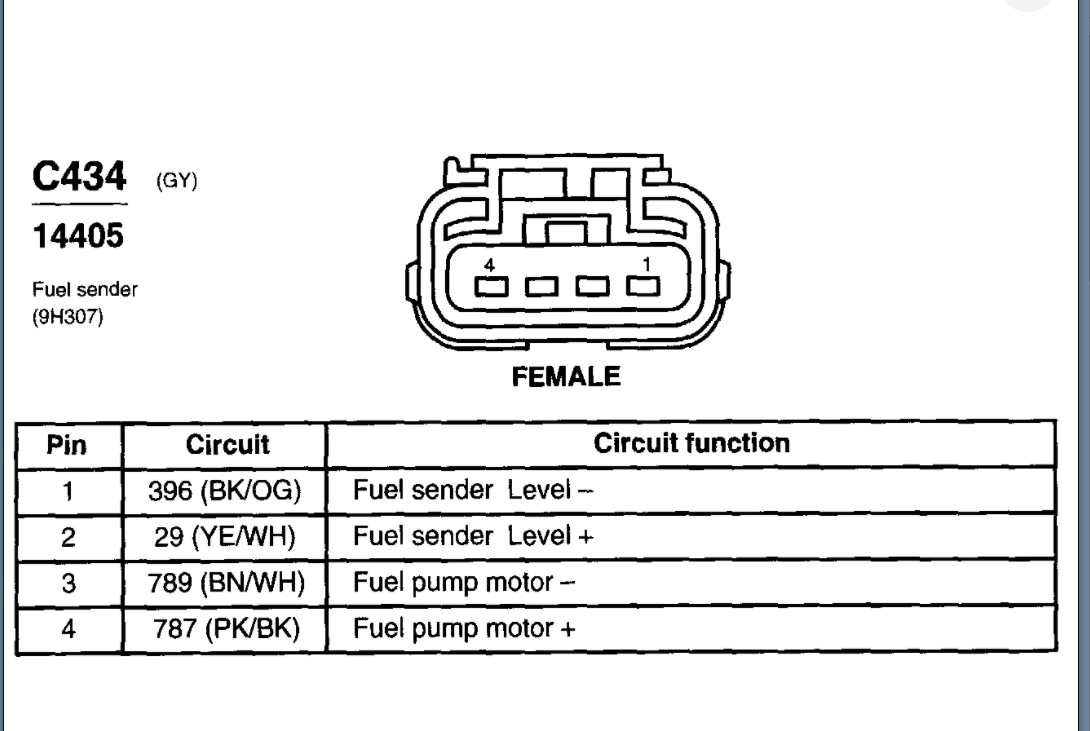

The second essential step is toconsult the wiring diagram specific to your vehicle's make, model, and year. Wiring diagrams provide precise color-coding information, circuit layouts, and component locations. Generic color codes are a good starting point, but manufacturer-specific diagrams offer the most reliable information. These diagrams are typically found in repair manuals or online databases.

Common mistakes include relying solely on generic color codes without verifying them against the specific wiring diagram. Another error is misinterpreting the diagram or overlooking variations due to trim levels or optional equipment. Always double-check that the diagram corresponds exactly to your vehicle.

3. Test the Wires

Once you have identified the wires and consulted the wiring diagram, the next step is totest the wires using a multimeter. This ensures that the power wire is receiving voltage, the ground wire has continuity, and the signal wire is functioning correctly (if applicable).

Power Wire: Test for +12V when the ignition is on. Ground Wire: Test for continuity to ground (zero resistance). Signal Wire:Test for a variable voltage or resistance that corresponds to the fuel level.

If you find that the power wire is not receiving voltage, check the fuel pump relay and fuse. If the ground wire does not have continuity, inspect the ground connection for corrosion or damage. If the signal wire is not functioning correctly, the fuel level sensor may be faulty.

Tips Before Using Color Coded Wiring Fuel Pump Wire Color Guide

Before diving into any fuel pump wiring project, there are several crucial preparation steps. First,disconnect the negative battery terminal. This prevents accidental short circuits that could damage your vehicle's electrical system or cause personal injury. Second, gather the necessary tools, including a multimeter, wire strippers, crimpers, and a wiring diagram specific to your vehicle. Third,*work in a well-lit and ventilated area. Fuel vapors are flammable, so avoid working near open flames or sources of ignition.

It's equally important to know what to avoid. Never cut or splice wires without consulting the wiring diagram. Avoid using cheap or incompatible connectors, as they can lead to poor connections and intermittent failures. Finally, never ignore warning signs such as burnt wires, melted connectors, or unusual odors. These signs indicate serious problems that need to be addressed immediately.

Ignoring these tips can have severe consequences. Failing to disconnect the battery can result in electrical shocks or damage to electronic components. Using incorrect wiring techniques can lead to short circuits, fires, or fuel system malfunctions. Overlooking warning signs can lead to more significant problems that require extensive and costly repairs.

Common Issues and Solutions Related to Color Coded Wiring Fuel Pump Wire Color Guide

One of the most common issues iscorrosion on the wiring connections. Corrosion can cause poor electrical contact, leading to intermittent fuel pump operation or complete failure. The solution involves cleaning the corroded connections with a wire brush or contact cleaner and applying a dielectric grease to prevent future corrosion.

Another common problem is*damaged or frayed wires. Wires can become damaged due to chafing, heat exposure, or physical stress. Damaged wires can cause short circuits or open circuits, resulting in fuel pump problems. The solution is to repair or replace the damaged wires using proper splicing and soldering techniques.

Sometimes, thewrong wiring diagram could be used, which can lead to misidentifying wires. This is particularly prevalent with older vehicles. Always confirm you have the correct diagram for the year, make, and model of the car.

Finally,incorrect wiring connections are another frequent issue. Even with color-coded wiring, it's possible to connect wires incorrectly, especially if you are working in a cramped space or under poor lighting conditions. The solution is to double-check all connections against the wiring diagram and use a multimeter to verify the correct circuit continuity and voltage. Thehow to Color Coded Wiring Fuel Pump Wire Color Guide is always important.

Conclusion

Color-coded wiring for fuel pumps offers a significant advantage for anyone working on automotive electrical systems. By providing a standardized system for identifying wires, it simplifies troubleshooting, reduces the risk of errors, and improves overall efficiency. However, it's crucial to remember that color codes are not universal and should always be verified against your vehicle's specific wiring diagram.

For optimal use, always disconnect the battery before starting any electrical work, gather the necessary tools, and consult the wiring diagram. Be mindful of common issues such as corrosion, damaged wires, and incorrect connections, and take steps to address them promptly.

By implementing color-coded wiring principles and following best practices, you can confidently diagnose and repair fuel pump problems, saving time and money while keeping your vehicle running smoothly. The key is to leverage the benefits of color coding while remaining vigilant and thorough in your diagnostic approach. MasteringColor Coded Wiring Fuel Pump Wire Color Guide makes automotive work more manageable, efficient, and safe.